|

NOVIDADES

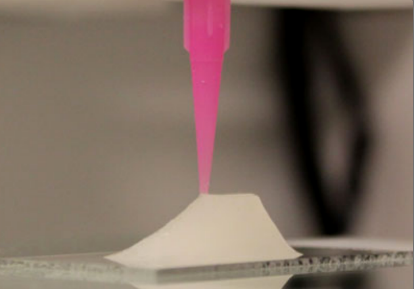

Bagasse is a waste plant matter obtained by food industry processes such as beer brewing, plant oil extraction or sugarcane processing for production of bioplastic. It is an underutilized agro-industrial residue that often gets incinerated to produce heat and electricity or used to make fodder. However, as new research shows, bagasse has great potential as raw material for the production of cellulose nanofibrils (CNF) for a range of applications (ACS Sustainable Chemistry & Engineering, "Pulping and pretreatment affect the characteristics of bagasse inks for 3D printing"). Researchers from Norway, Argentina and Sweden have developed a CNF ink from bagasse that has potential as component in bioinks for 3D printing. Bioinks are inks that contain living cells and that can be 3D printed in a cell-friendly manner, without compromising cell viability. Cellulose nanofibrils are of great interest for the design and manufacture of nanopaper, nanocomposite materials, and even biomedical applications (read more: "Nanotechnology in the pulp and paper industry"). Typically having lengths in the micrometer scale and widths in the nanometer scale (<20 nm), the morphology and surface chemistry of CNF can be tailored by different chemical and enzymatic pretreatments and processing steps.  3D printing of a nanocellulose construct. Image: Gary Chinga Carrasco, RISE PFI AS

Finally, the resulting CNFs were characterized in detail – morphology, surface chemistry, cytotoxicity – and assessed as inks for 3D printing. Especially nanocellulose for biomedical applications requires a thorough assessment in order to secure its biocompatibility with the human body and its use in biomedical devices such as wound dressings. To demonstrate the capabilities of their ink, the researchers printed 3D models of ears and noses, which shows the potential of the material to 3D print constructs from an agro-industrial residue. The researchers will continue work on optimizing the pulping process in order to obtain an ink that provides optimal print quality without compromising its biocompatibility. By Michael Berger – Michael is author of two books by the Royal Society of Chemistry: Nano-Society: Pushing the Boundaries of Technology and Nanotechnology: The Future is Tiny. Nanowerk. Posted: Feb 22, 2018. Assuntos Conexos: |

|||||||||||||||||||||||||