|

NOVIDADES

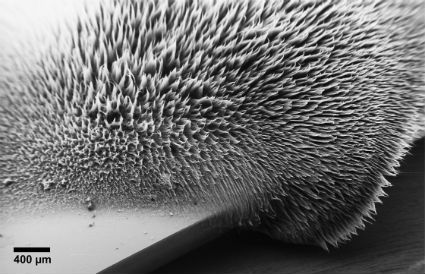

Swedish researchers have discovered a new and efficient way to use electrocatalysis to produce hydrogen gas from water. Instead of using expensive and difficult-to-obtain platinum electrodes, the new method uses electrodes with nanotruss structures of iron oxide. The research is led by Professor Ulf Helmersson. The Plasma and Coatings Physics research group at Linköping University manufactures thin films of nanomaterials. To do this, the researchers use a technique known as “pulsed plasma sputtering”. The basic process, sputtering, is a commonly used coating method used in industry and research. Atoms are sputtered onto a substrate in a chamber to form a thin layer of constant thickness, with the aid of ionised gas. The LiU researchers have further developed the technique and use short but highly efficient pulses of a plasma in order to cause nanoparticles of the sputtered atoms to grow. The nanoparticles grow as they float in the gas. However, in one of the experiments run by Sebastian Ekeroth, doctoral student in plasma and coatings physics, the material turned out to have formed in completely the wrong place. Professor Ulf Helmersson realised the significance of the findings, and a new research field based on ferromagnetic nanostructures was founded. Researchers around the world are becoming ever more interested in ferromagnetic nanoparticles and how they can be produced, in particular in various types of solution. These magnetic materials are becoming increasingly interesting for energy storage (with a special interest in the storage of energy from renewable sources), catalysis, and the synthesis of chemicals. The group at LiU, in collaboration with researchers at Umeå University, has developed a method to control the production of ferromagnetic nanostructures with the aid of pulsed plasma sputtering. The result has been published in the prestigious journal Nanoletters.  Overview of Fe nanotrusses covering the surface and edge of a Si substrate. Photo Credit: Robert Boydoch Thor Balkhed.

“The way in which the iron particles hook into each other gives a very stable structure. The environment in an electrolyte can be very rough-and-tumble. If the conductivity is to be preserved until the end of the process, it’s important that the structure doesn’t break up”, says Sebastian Ekeroth.  Zoom in on a tip of a nanotruss where individual nanowires are clearly visible. The method can also be used for large areas. Photo credit: Thor Balkhed

This electrode has many advantages over expensive electrodes made from the difficult-to-obtain platinum. The new electrode is lightweight, can be bent, has a high capacity, and is composed solely of environmentally friendly and easily sourced substances, namely iron, oxygen and carbon. The hydrogen gas has a high energy content. When the chemical energy in the hydrogen is converted to electrical energy in a fuel cell, the only waste product formed is water. Interest in fuel cells is increasing steadily, principally for environmental reasons. However, 96% of the hydrogen currently produced comes from non-renewable sources. The hunt is on for more environmentally sensitive methods of producing hydrogen. The latter is also a potential energy-carrier, and thus a possible medium for storing energy obtained from, for example, solar sources or wind power. “The production of hydrogen is one important application, but we are also looking at other areas, such as electrodes in batteries, in supercapacitors, and for use in photocatalysis”, says Ulf Helmersson. Catalytic Nanotruss Structures Realized by Magnetic Self-Assembly in Pulsed Plasma, Sebastian Ekeroth, E. Peter Münger, Robert Boyd, Joakim Ekspong, Thomas Wågberg, Ludvig Edman, Nils Brenning and Ulf Helmersson, Nano Letters 2018, DOI 10.1021/acs.nanolett.8b00718. By Monica Westman Svenselius. Linköping University. Posted: July 18, 2018. |

|||||||||||||||||||||||||