|

NOVIDADES

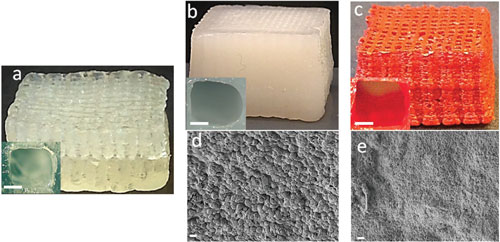

For instance, nanocellulose dramatically improves the 3D-printability of carbon nanotubes for wearable electronics. Researchers are also equipping nanocellulose with additional functionalities to produce implants for cartilage diseases using 3D printing. In addition, printed cellulose has advanced applications such as printed electronics, biomedical devices, energy storage, construction, separations, cosmetic, and food applications. 3D printing of nanocellulose has been reported using several methods, including matrix-assisted 3D printing, direct ink writing, and stereolithography. Reporting their work in Advanced Functional Materials("CelloMOF: Nanocellulose Enabled 3D Printing of Metal–Organic Frameworks"), researchers at Stockholm University have recently demonstrated a 3D printable hydrogel ink containing metal-organic frameworks (MOFs). The synthesis and printing processes take place at room temperature using water as a solvent.  a–c) Photos of 3D printed scaffolds: TOCNF, 4CelloZIF8, and 4CelloZIF8-Cur. Insets are images representing the pores, with the scale bar of 0.5 mm. d,e) SEM images of scaffold b, 4CelloZIF8 and scaffold c, 4CelloZIF8-Cur. Scale bar = 1 µm. Reprinted with permission by Wiley-VCH Verlag

This synthesis approach can be used to encapsulate drugs such as curcumin and methylene blue into the CelloMOF systems. The hybrid inks are printed using simple and inexpensive 3D printer, which can be used by both experts and nonspecialists, extending the use of 3D-printed CelloMOFs in several applications, including water purification, air purification, catalysis, sensors, etc. "We believe that this work provides a new proof-of-concept prospect for MOFs processing that is flexible, simple, fast, promising for large-scale production and for uptake and release of a variety of guest molecules," trhe authors conclude their report. By Michael Berger. Posted: Apr 15, 2019. |

|||||||||||||||||||||||||