|

NOVIDADES

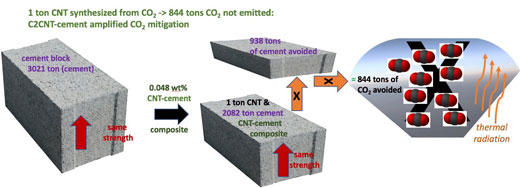

A peer reviewed study released in Materials Today Sustainability ("Amplified CO2 reduction of greenhouse gas emissions with C2CNT carbon nanotube composites") provides a several hundred-fold advance in stopping the release of the greenhouse gas carbon dioxide. This ground-breaking advance utilizes CO2 in producing carbon nanotubes which when, added to materials such as concrete or steel, forms composites with significantly better properties. This is achieved at a fraction of the current cost of manufacturing carbon nanotubes and results in a cost of carbon savings in the materials production dramatically below the current cost of carbon mitigation. Furthermore, the removed CO2 is permanently stored, unlike, other methods like the production of fuels or seltzer water that re-release CO2 when the product is used. The study is by the C2CNT team that previously demonstrated a process to transform CO2 to Carbon Nanotubes (C2CNT). The C2CNT team is a Finalist in the Carbon XPrize international competition (CarbonXPrize.org, team website C2CNT) to produce the most valuable product from the CO2 in flue gas.  (Image: S. Licht, C2CNT)

– 4400 tons of CO2 in aluminum production, – 2750 tons of CO2 in titanium production, – 1800 tons of CO2 in magnesium production, or – 300 tons of CO2 steel production. The strength of CNT-composites had been widely recognized, but not previously connected with an environmental benefit due to the very high cost and high carbon footprint of the production of available commercial CNTs. In this discovery of the C2CNT-composite process, carbon nanotubes are produced by electrolysis at low cost using, rather than releasing, CO2, and then mixed with the structural material. The new C2CNT-composite process would allow for example the entire greenhouse gas emission of a fossil fuel power plant to be offset (not eliminated, the CO2 emission is eliminated at a structural material plant) with a small, onsite C2CNT plant producing carbon nanotubes. Alternatively, the CO2 can be removed directly from the air to offset a structural material plant’s greenhouse gas emission. Massive consumption and removal of CO2 can minimize the species extinction, disruption to the global economy, climate change hurricanes, floods and droughts and prevent global warming from changing life as we know it. C2CNT is on path to a nanocarbon based economy aimed at changes comparable to the introduction of the plastics economy. The nanocarbon economy consumes CO2 and improves common products, such as more powerful batteries, taller buildings, stronger bridges, lighter vehicles and airplanes, bullet & shock proof thin clothing and through carbon nanomaterials made from CO2. According to Prof. Licht: The purpose of our 'Diamonds from the sky' technology in transforming anthropogenic carbon dioxide to valuable carbon nanomaterials and composites is to incentivize reduction of this greenhouse gas and pioneer a nanocarbon economy to save the planet from the ravages of climate change. Advanced Sustainable Systems: "Carbon Nano-Onions Made Directly from CO2 by Molten Electrolysis for Greenhouse Gas Mitigation". C2CNT. Accessed: Sept 05, 2019. |

|||||||||||||||||||||||||